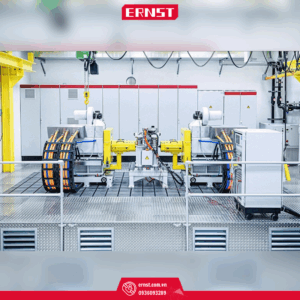

Non road test bed John Deere

Views & drawings Properties & technical data Application: Non Road (Harvesting) Test bed mass: 15000 kg Height adjustment: ± 1375 mm Braking power: 810 kW (dependent on rotational speed) Speed

Views & drawings Properties & technical data Application: Non Road (Harvesting) Test bed mass: 15000 kg Height adjustment: ± 1375 mm Braking power: 810 kW (dependent on rotational speed) Speed

Views & drawings Properties & technical data Base frame Turbocharger Application: Hot gas test bed of marine/ large engines Gas forces: up to 260 kN Power: up to 45000 kW Pressure

An additional intermediate bearing is often included in the shaft connection of high-speed test beds. ERNST offers a wide range of bearing positions according to the required speedrange as well

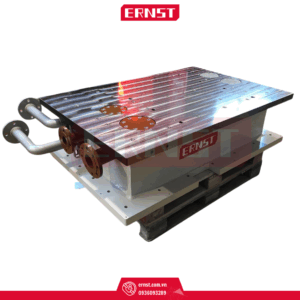

Quick couplings enable the fast and leak-free coupling of liquid and gaseous media. All quick couplings are locking couplings, which means that in the uncoupled state the passage is blocked

The requirements for occupational safety are continuously increasing. A shaft guard as a mechanical protection device is now the standard to protect both personnel and adjacent components in case of

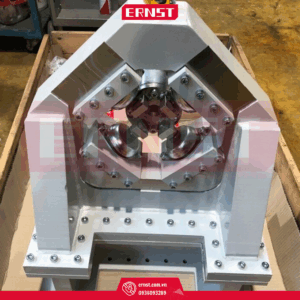

Large components, such as base structures and head stock, now form the foundation of high-speed test beds. In addition to the FEM simulations to determine the stiffness, the correct manufacturing

The B-side support was originally developed in the course of a specific application to reduce the vibration velocities occurring on the DUT. The additional support is particularly helpful with a

Ngoài các hệ thống hoàn chỉnh, ERNST còn cung cấp các linh kiện thử nghiệm riêng lẻ để cải tiến các máy móc hiện có. Các linh kiện hiện có