ERNST’s static test beds provide our customers with enormous flexibility, precise measuring capabilities and state-of-the-art data acquisition.

Thus, the structural strength of the test specimens can be recorded and documented easily, ergonomically and meticulously.

Overview of static test beds

1. Side compression system

The side compression system is used to test the vehicle structure according to the FMVSS 214s test regulation, but is also used for numerous customer-specific special tests.

Depending on the test configuration, the pressure post can be increased in 50 mm increments. The integrated line laser makes it easy to align the structure to be tested with the pile.

The system can be moved 300 mm in height via an electric hoist.

Force measurement is performed as standard with 2 triaxial load cells, each with 250 kN nominal force in X, and 100 kN in Y and Z directions.

The system is characterized by its extremely rigid design, which keeps the system-specific deformations to a minimum. The travel distance, free from the influence of force, can be measured via a separate wire-actuated potentiometer.

Properties

- Compressive and tensile force: 300 kN at 15 mm/s feed rate

- Stroke: 750 mm max.

- Optional: 6-axis load cells

- Customer-specific special requests can be implemented at any time

Details

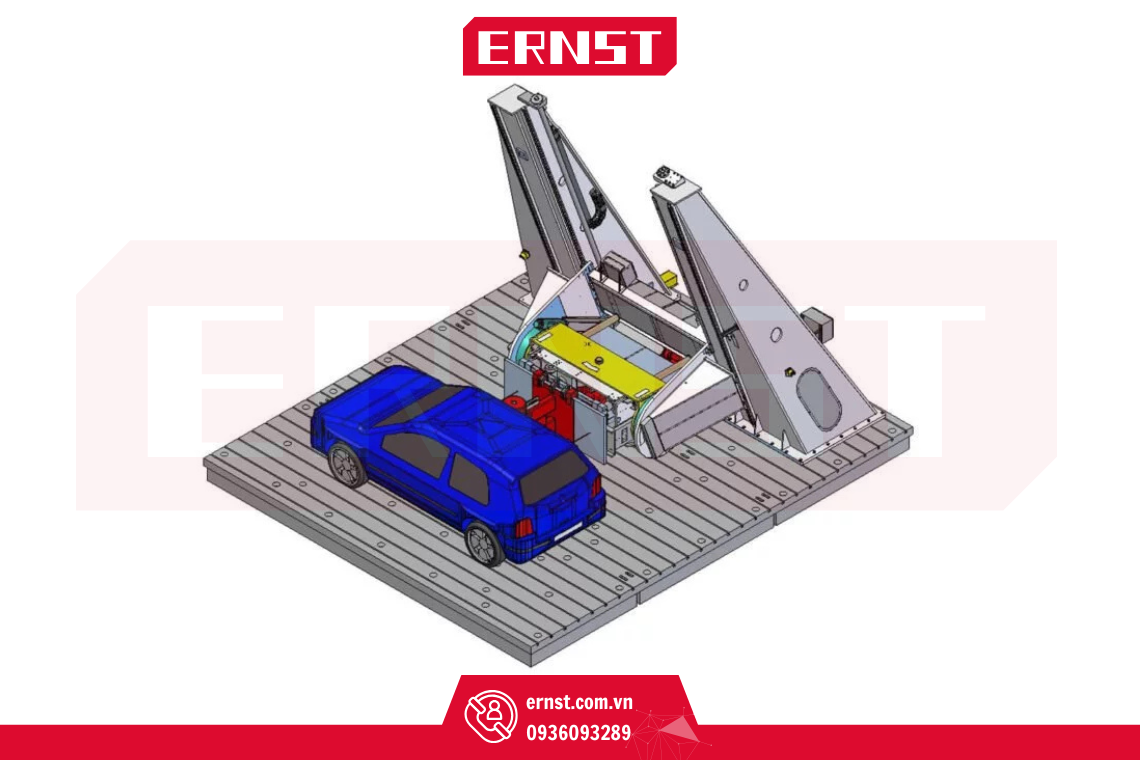

2. Combined compression system

The roof compression system is used to test the vehicle structure according to the FMVSS 216a, FMVSS 214s and IIHS (Roof Strength Test Protocol) test regulations, but is also used for numerous, customer-specific special tests.

Depending on the test configuration, the pressure plate can be continuously tilted by two angles, -25 to +95 degrees around the X-axis and ±5 degrees around the Y-axis.

The cross laser integrated in the plate at the first contact point enables easy alignment of the pressure plate with the UUT.

All 5 axes are electrically driven and allow extremely precise control via a mobile control unit.

The compression plunger for lateral compression tests can be easily attached to the horizontally positioned compression plate.

Force measurement is performed as standard with 4 single-axis load cells, each with 250 kN nominal. The system is characterized by its extremely rigid design, which keeps the system-specific deformations to a minimum.

The travel distance, free from the influence of force, can be measured via a separate wire-actuated potentiometer.

Properties

- Compressive and tensile force: 250 kN at 15 mm/s feed rate

- Stroke: max. 1000 mm

- Optional: 3-axis load cells

- Customer-specific special requests can be implemented at any time

3. Roof compression system

The roof compression system is used to test the roof structure according to the FMVSS 216a and IIHS (Roof Strength Test Protocol) test regulations, but is also used for numerous, customer-specific special tests.

Depending on the test configuration, the pressure plate can be continuously tilted by two angles, ±25 degrees around the X-axis and ±5 degrees around the Y-axis. The cross laser integrated in the plate at the first contact point enables easy alignment of the pressure plate with the UUT.

All 5 axes are electrically driven and allow extremely precise control via a mobile control unit.

Force measurement is performed as standard with 4 single-axis load cells, each with 250 kN nominal.

The system is characterized by its extremely rigid design, which keeps the system-specific deformations to a minimum. The travel distance, free from the influence of force, can be measured via a separate wire-actuated potentiometer.

Properties

- Compressive and tensile force: 250 kN at 15 mm/s feed rate

- Stroke: 1000 mm max.

- Optional: 3-axis load cells

- Customer-specific special requests can be implemented at any time

4. Seat test bed

A seat test bed is used to perform static load tests on the vehicle seat and is specially designed for material testing of seats or head restraints.

Seat testing is carried out in accordance with the relevant standards, including FIA Standard 8855-2021, FIA Standard 8862-2009, UN ECE 17, R25, FMVSS 202 as well as GB 15083-2006, but can also be used for customer-specific tests. Mechanical adjustments and corresponding, freely definable software parameters are possible.

The test stand includes several electric cylinders. Each cylinder is equipped with a load cell and a linear displacement sensor and is driven by an electric motor.

The administration of the test definitions with parameters, display screens and editors, authorization system, monitoring and measurement data takes place in the associated automation system.

Before starting the test, all necessary test parameters can be set. The load curve (force, moment vs. time) can be carried out in parallel on up to three electric cylinders.

After starting the test, the electric cylinders are automatically controlled by a software algorithm that includes a closed control loop between the inverter and the measured force/displacement.

The test bed is characterized by its stable design and configured for testing seats with floor mounting or floor and seat-back mounting.

Details